TRADESHOW ARTIFACTS

OVERVIEW

Equispheres is a materials science company that develops high-performance spherical metal powders for metal 3D printing, using a patent-pending atomization process to improve efficiency, quality, and scalability in additive manufacturing.

During my time at Equispheres Inc., I led the design of a series of tradeshow artifacts created to showcase the performance and advantages of the company’s engineered metal powders for additive manufacturing. I was responsible for research, concept development, and CAD modelling, as well as creating interactive 3D visualizations that helped communicate each artifact’s function and complexity to customers. These contributions played a key role in elevating Equispheres’ presence at Rapid + TCT in Los Angeles, resulting in the company’s strongest show performance to date and significantly boosting booth engagement and customer interest.

Context

Equispheres Inc. (Internship)

Year

2024

RESEARCH

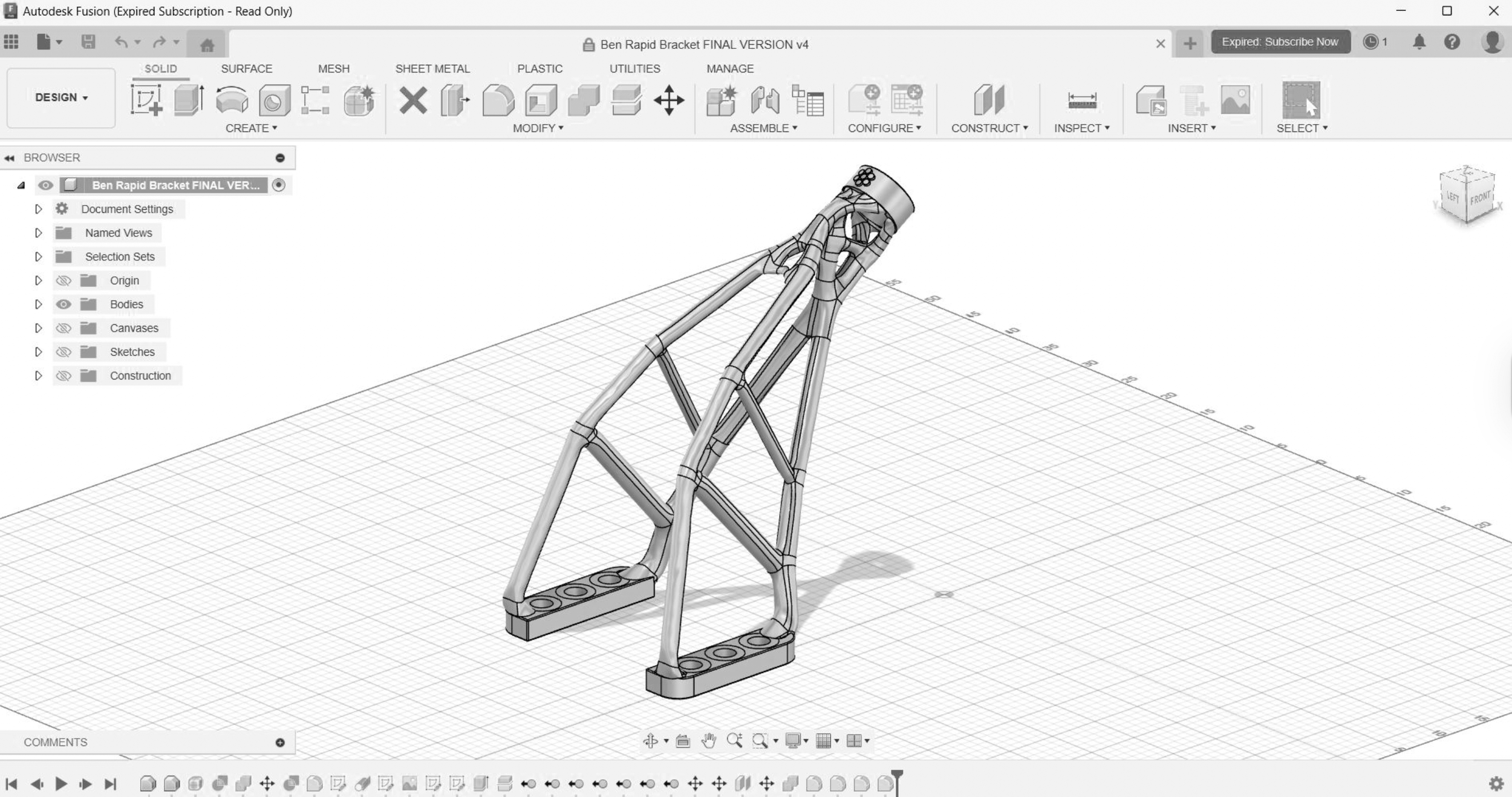

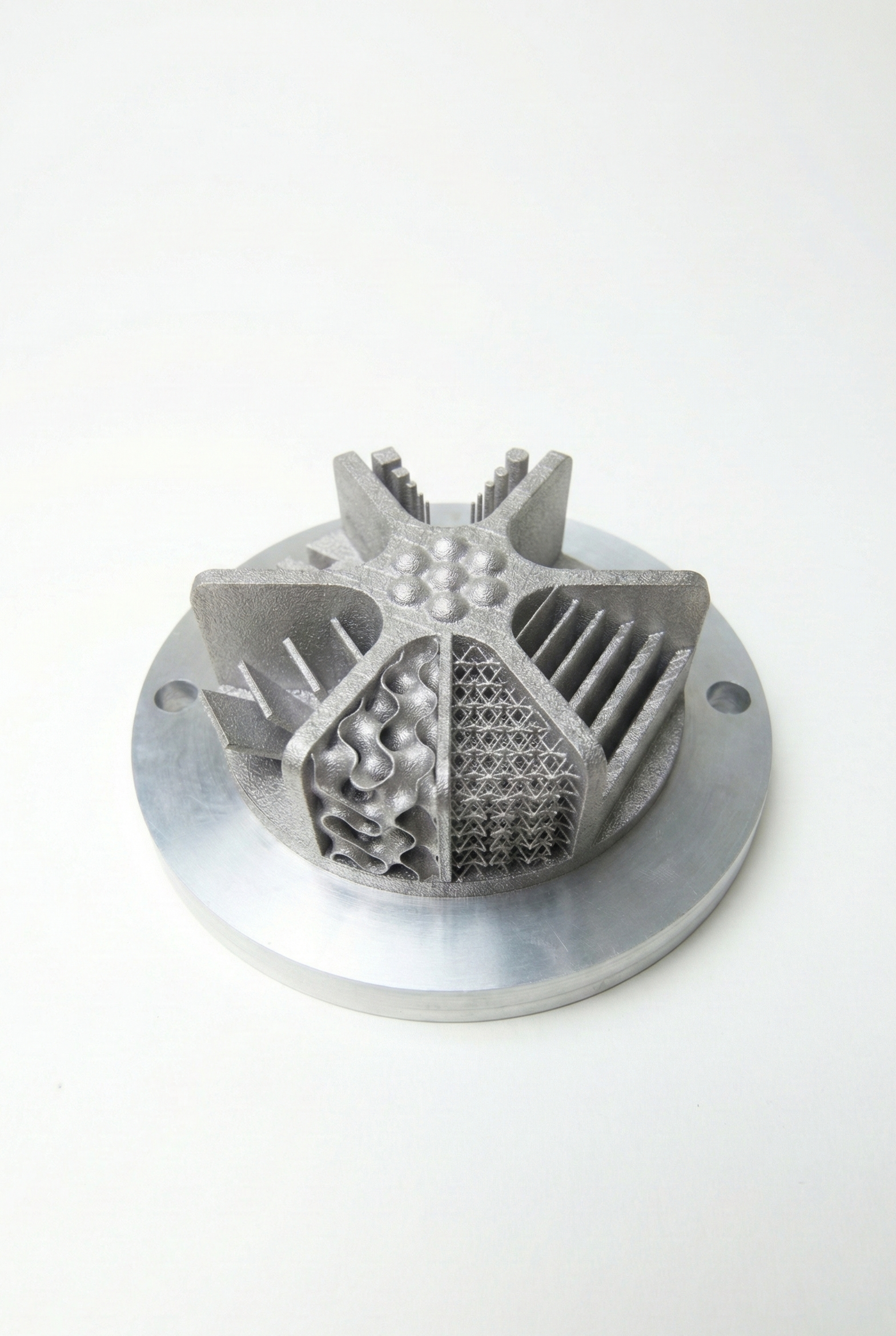

Designing for metal additive manufacturing required a deep dive into new technical territory. Through focused research and internal discussions, I built a strong understanding of metal AM principles and defined the key stories each tradeshow artifact needed to communicate. This led to two strategic directions: a satellite mounting bracket for aerospace applications demonstrating fast print speeds and reduced build time and part cost compared to traditional manufacturing methods. The second was a compact heat exchanger showcasing fine-feature precision and complex lattice geometries. This foundation ensured the artifacts weren’t just visually appealing, but clearly conveyed the performance advantages of Equispheres’ metal powders.

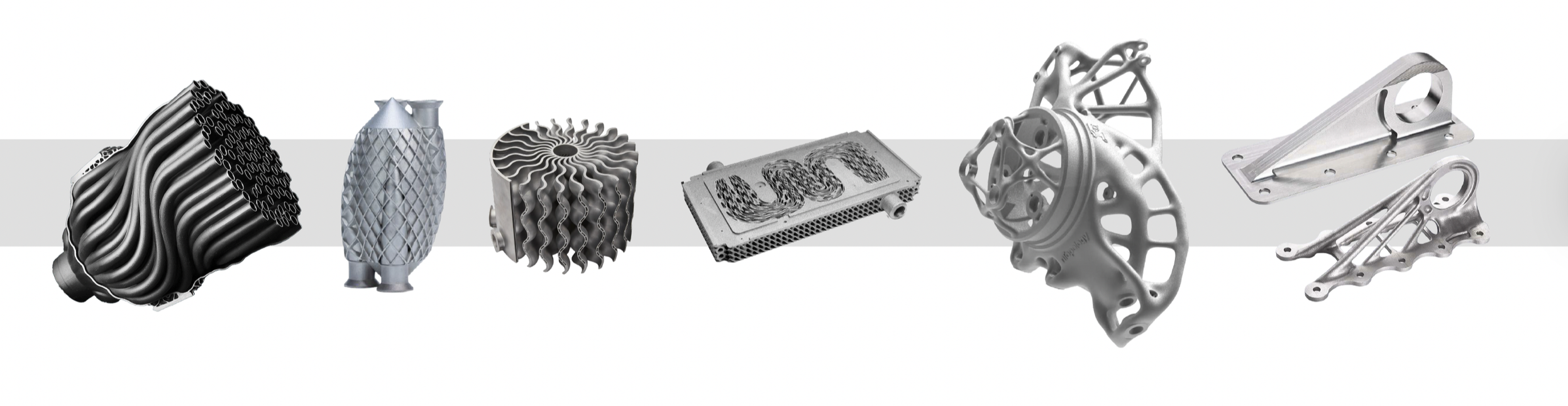

Market analysis exploring existing metal AM applications, benchmark parts, and key target industries.

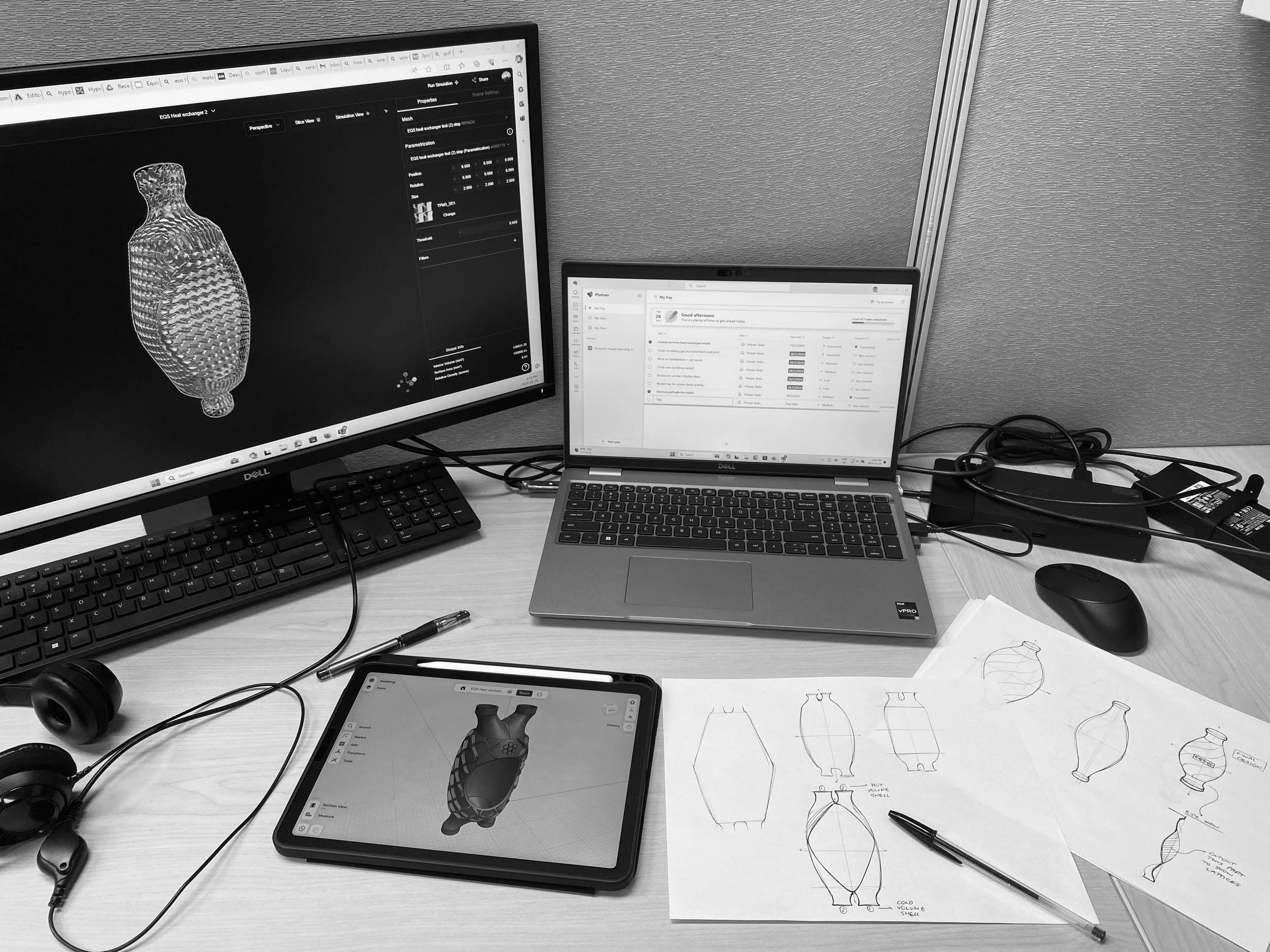

DESIGN PROCESS

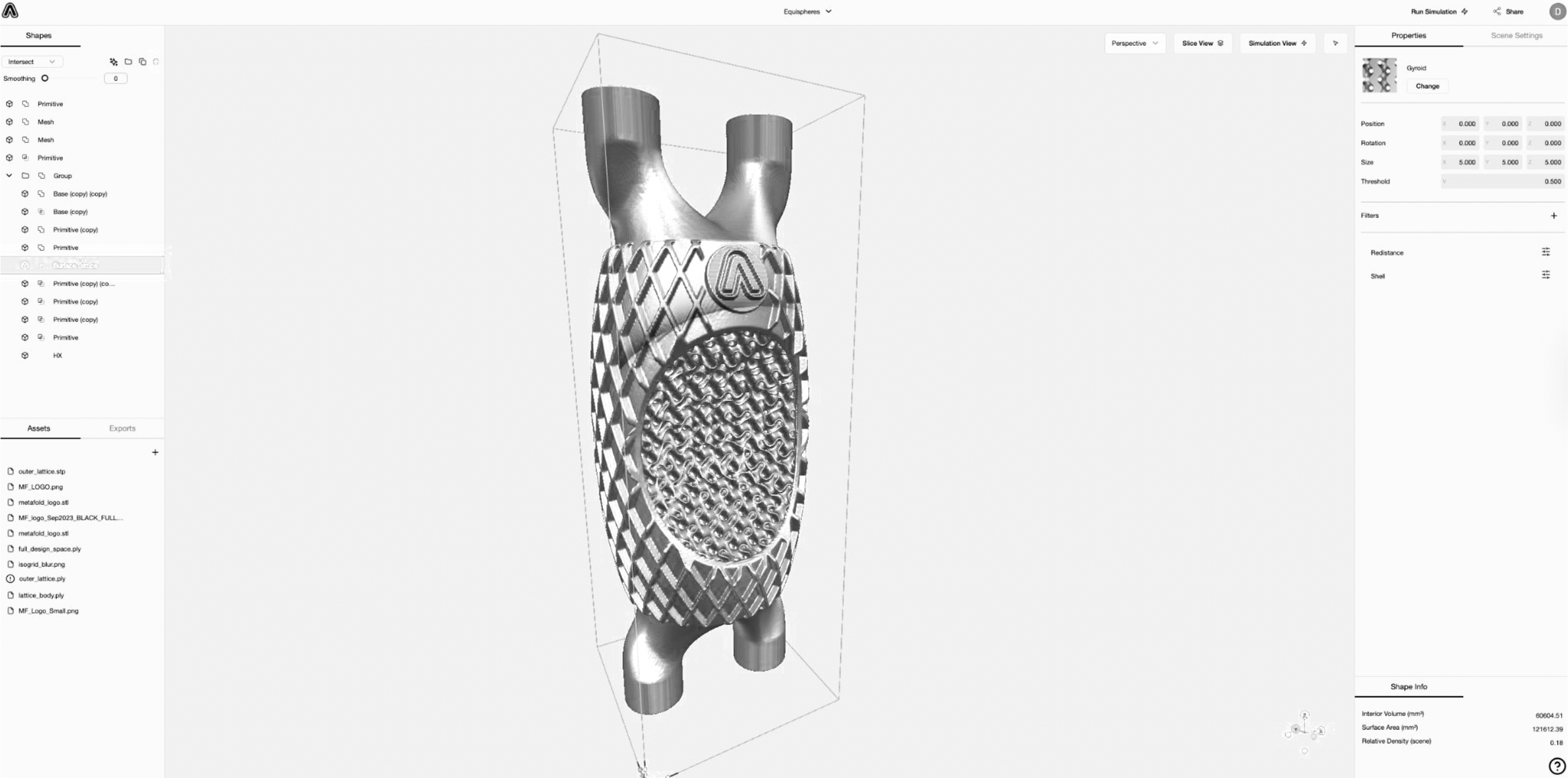

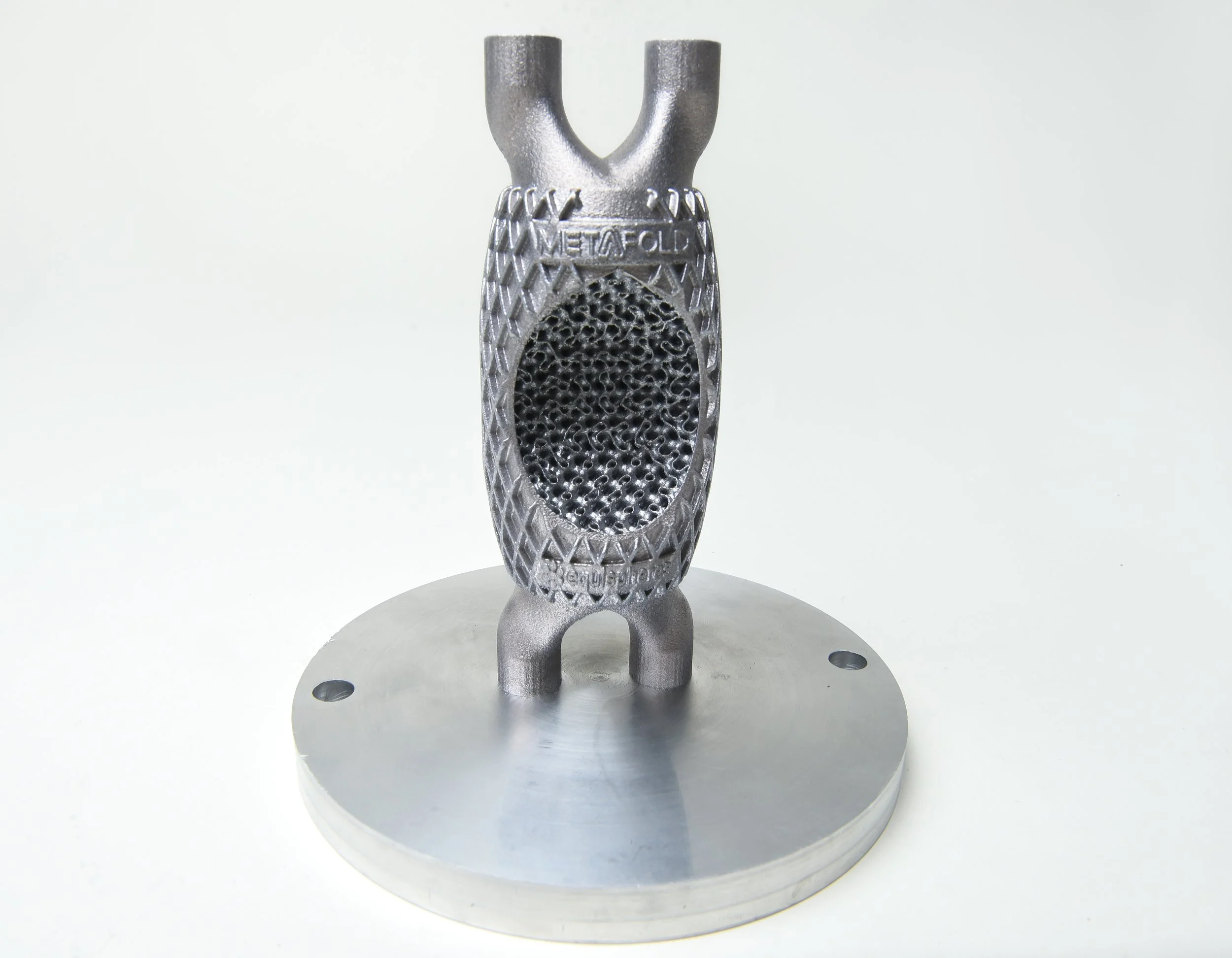

With a clear direction established, I moved into concept development and began designing both artifacts in parallel. The satellite bracket was created using generative design in Fusion 360 and printed externally due to in-house size limitations. The heat exchanger followed a multi-software workflow. I collaborated with Metafold 3D to develop the internal gyroid lattice, then refined the model in Netfabb to reduce overhangs and support structures before preparing it for printing.

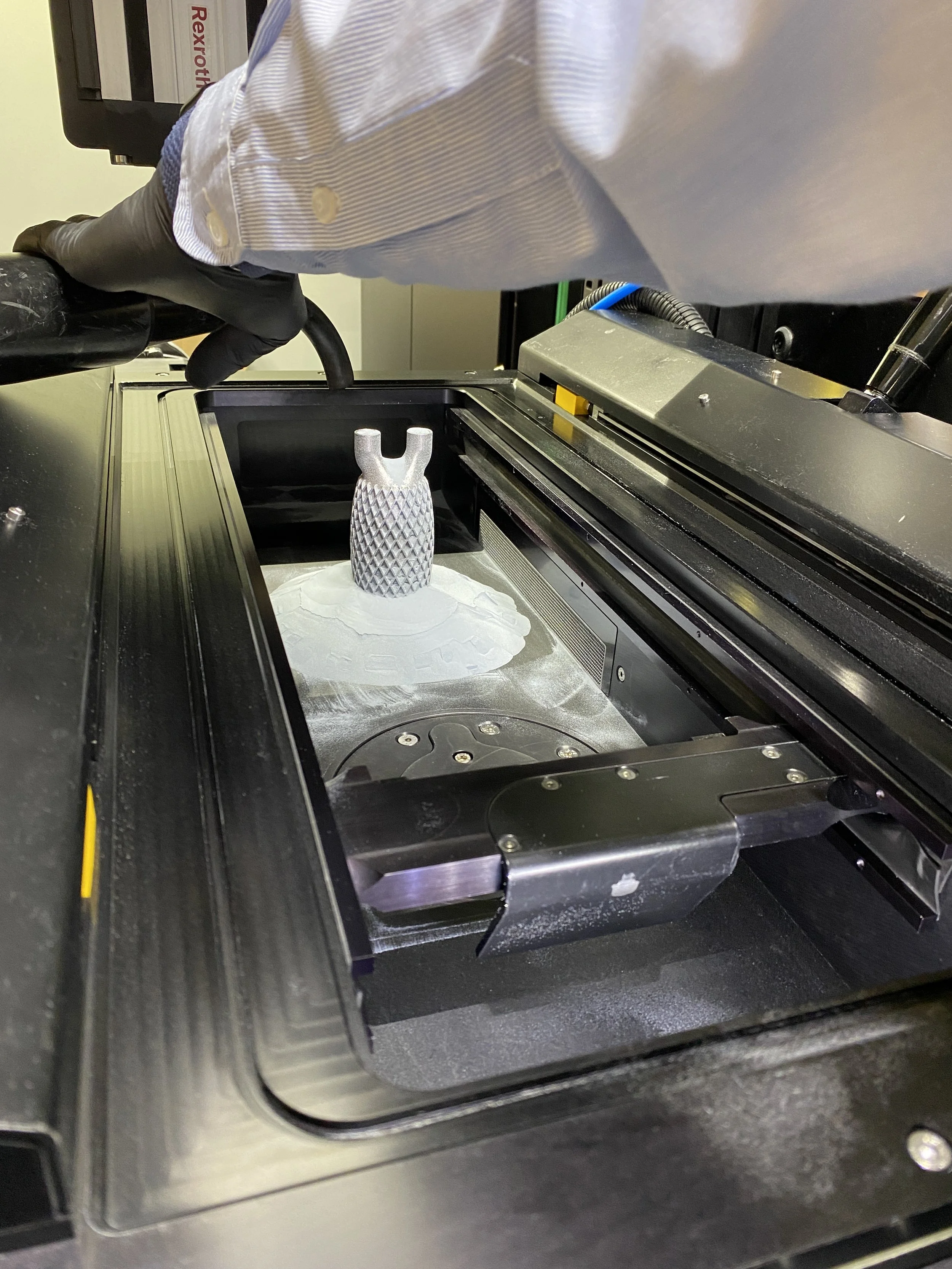

PRINTING PROCESS

The heat exchanger was produced on Equispheres’ in-house AconityMINI system, a compact Laser Powder Bed Fusion (LPBF) printer, using Equispheres’ NExP-1 AlSi10Mg powder. Printed at a 60 μm layer thickness and a build rate of 45 cm³/hr, the part required no post-processing beyond ultrasonic cleaning to remove excess powder. The result was a high-precision component that showcased excellent surface quality and the ability to print intricate features such as the internal gyroid lattice.

RAPID + TCT TRADESHOW

The final artifacts were showcased at Rapid + TCT alongside interactive 3D visualizations I designed, allowing attendees to explore each part’s geometry, purpose, and manufacturing story. Together, these elements contributed to Equispheres’ strongest tradeshow presence to date.