ARVIA SYSTEM

by koto design

OVERVIEW

In collaboration with Manuel Chavez-Vasquez, we designed the Arvia System - a modular, sustainable furniture solution developed over a 12-week university project under our brand, Koto Design. Made for makers, students, and compact living, Arvia functions as a shelf or table and reconfigures to fit any space. Built with 3D-printed joinery, responsibly sourced plywood, and upcycled polypropylene panels, it emphasizes low-waste, adaptable construction. The tool-free assembly uses an internal dowel-locking mechanism and foldable slat shelves, allowing the entire system to pack into a single bag. The result is a lightweight, portable, and durable furniture system rooted in minimalist, sustainable design.

Context

University Project

Year

2024

Shelving shouldn’t feel permanent. But nowadays, it does.

Most shelving systems are bulky, hard to relocate, and rely on tools and fasteners that complicate assembly. Disassembly is difficult, meaning reuse, repair, and recycling become almost impossible. They’re built to stay in one place - even when people aren’t. So how can we design an elegant system that’s adaptable, simple to assemble, and easy to repair?

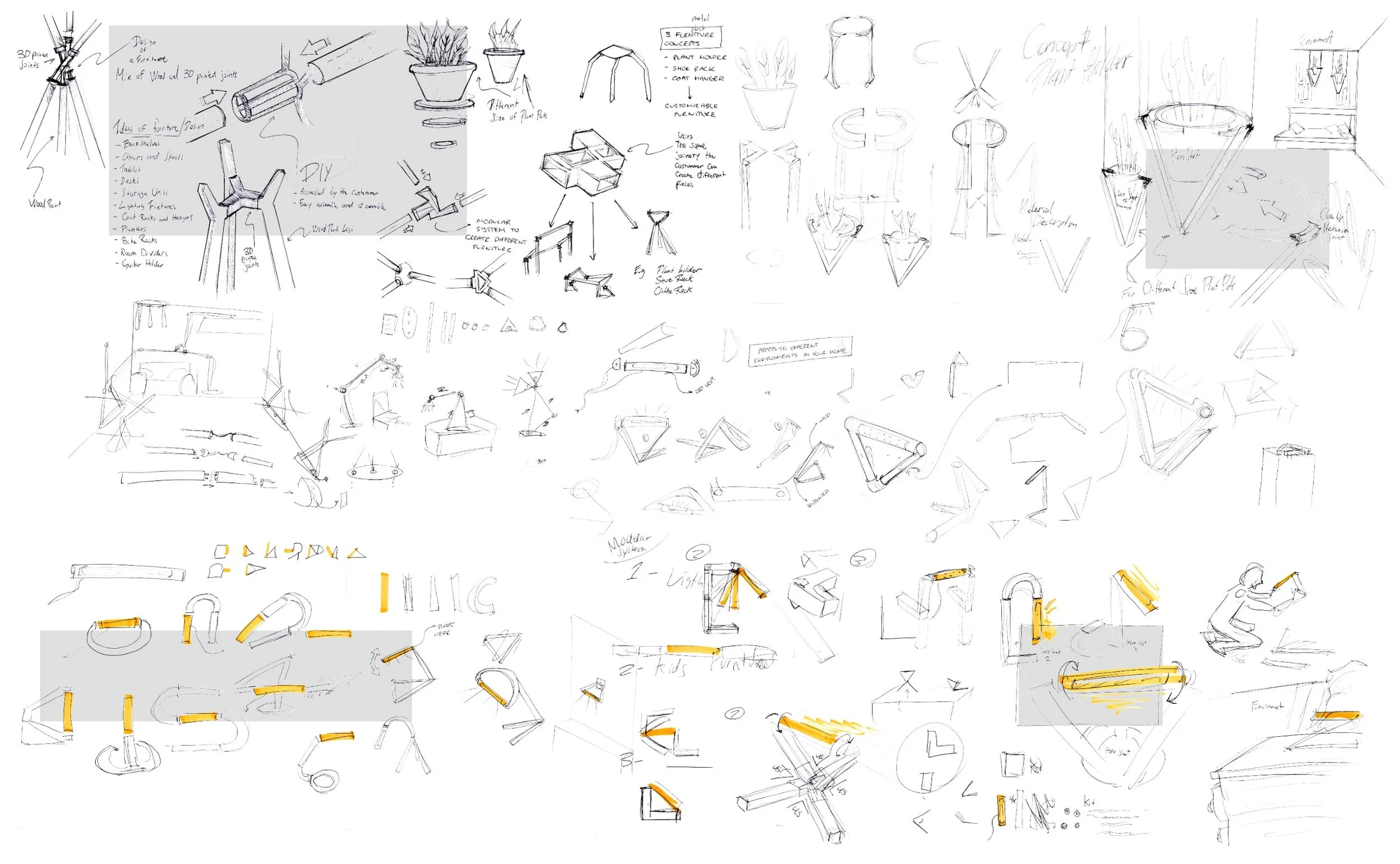

IDEATION

In the early stages, we focused on how sustainable materials and innovative joinery could shape a simple, adaptable product system that was easy to assemble and manufacture. We sketched broadly, exploring concepts for indoor, outdoor, and even child-focused environments to understand the full potential of a modular approach. Through iterative sketching and discussion, we refined our direction to two concepts that strike a balance between usability, sustainability, and everyday practicality.

PROTOTYPING

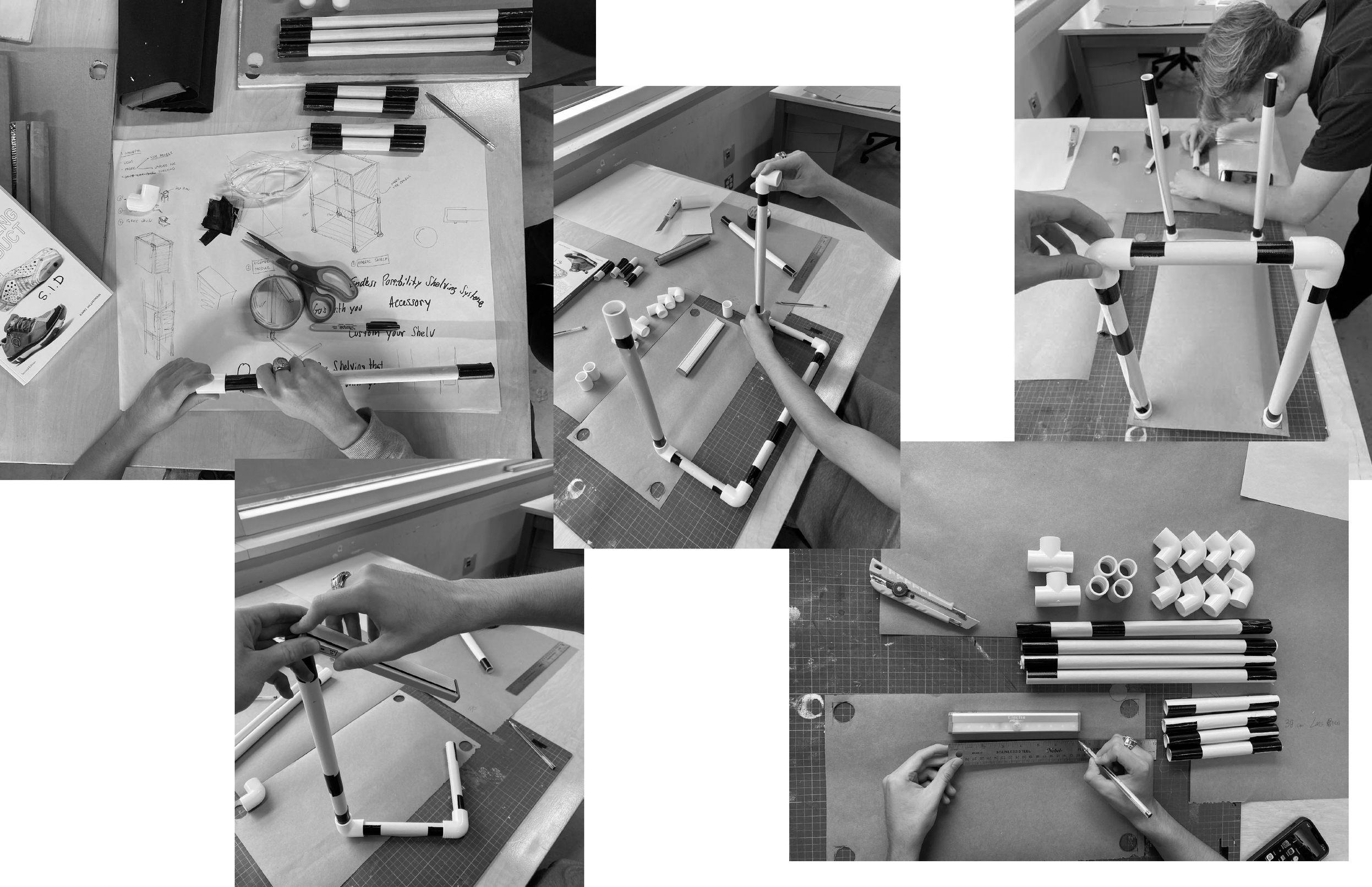

Following feedback from our professor and peers, we saw an opportunity to evolve our initial concepts into a second-generation system - one that could compete with modular standards like IKEA’s Kallax. We began prototyping a furniture system capable of transforming into multiple configurations to support different uses. Throughout this phase, we focused on sustainability, intuitive assembly, and seamless integration.

We began with field research at IKEA, studying the Kallax system to identify opportunities for modularity and simplicity. Our first low-fidelity prototype, constructed from cardboard, paper, tape, and a small light module, enabled rapid testing of configurations, scale, and ergonomic needs while sketching in parallel to refine our ideas. Through this exploration, we discovered that the dowels needed to be taller and the recycled fabric panels required greater tension. This phase revealed the project’s defining innovation: reimagining the shelf as a slatted structure supported by fabric, enabling true portability.

For our second prototype, we used cardboard, plastic piping connectors, and hardware-store materials to build a more accurate and testable model. This iteration helped us refine measurements, assess structural needs, and experiment with more reliable configurations. Through this process, we identified the need for a locking system, as the dowels and connectors lacked stability, and recognized that adding an external groove to the straight connectors would prevent unwanted movement in the shelving.

In this phase, we moved to stronger materials, full-scale wooden dowels and a stabilized wooden base, to validate dimensions and finalize configurations. This prototype confirmed structural integrity and clarified the direction for our final design. Key insights included the need for thicker dowels, added feet for stability, and potentially adjustable O-ring joinery for customizable shelf heights.

In the final prototyping stage, we refined the system using higher-quality materials, tested the slatted shelves with fabric panels, and adjusted hole spacing to lock in accurate dimensions. We also began trial-and-error testing with 3D-printed connectors to improve assembly and stability. Key insights included the importance of precise hole placement, proper fabric tension for the side panels, and continued refinement of the connectors for strength and usability. This phase solidified the system’s materials, dimensions, and modular functionality, allowing us to build a functional final model.

moves with you.

moves with you.

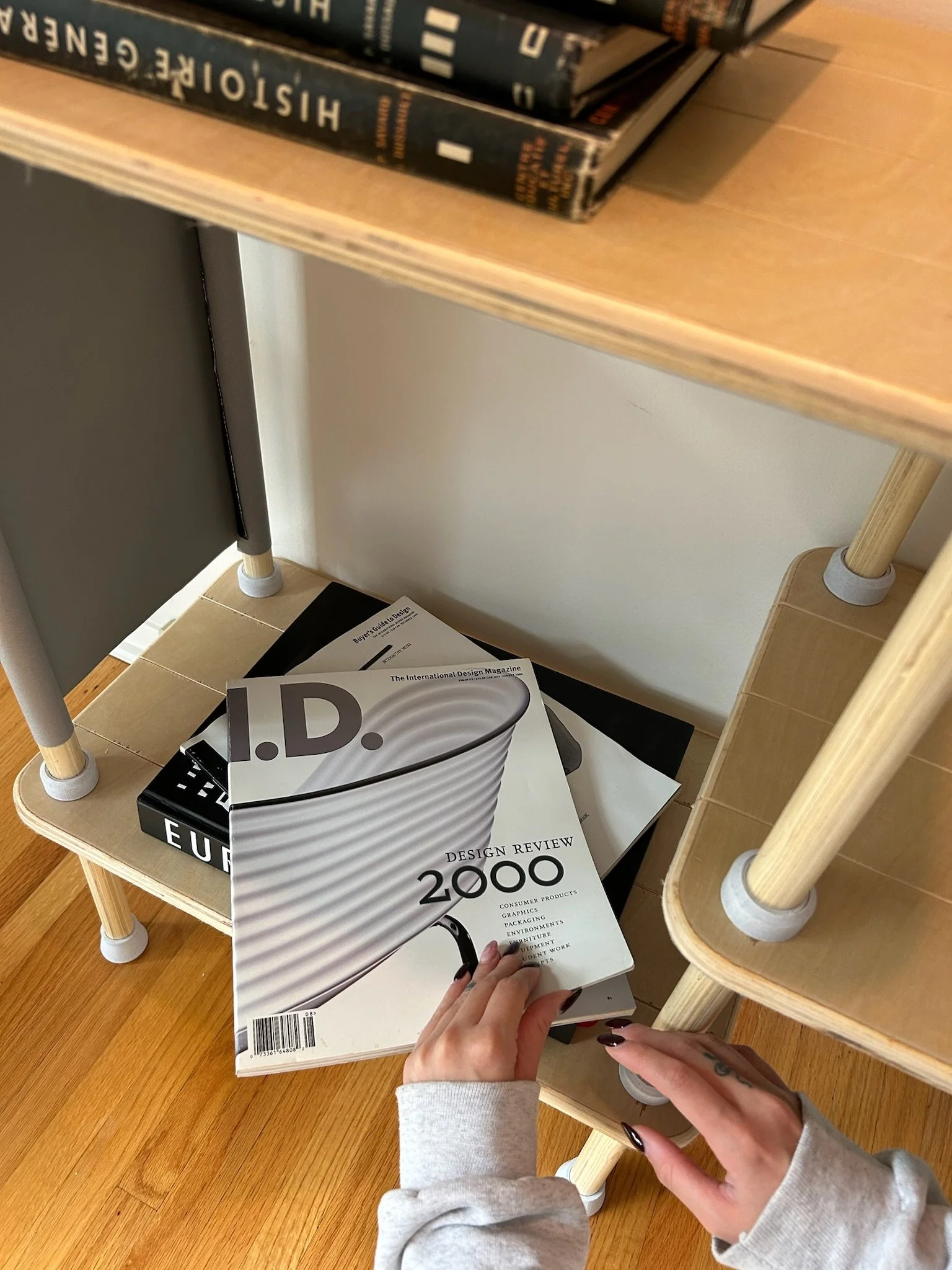

USER INTERACTION

Screwing joinery for effortless assembly.

Secure internal dowel locking means no fasteners.

Foldable slat shelves for complete portability.

CONFIGURATIONS

Table mode. Compact shelf. Expanded shelf.

The Arvia System is designed to adapt.

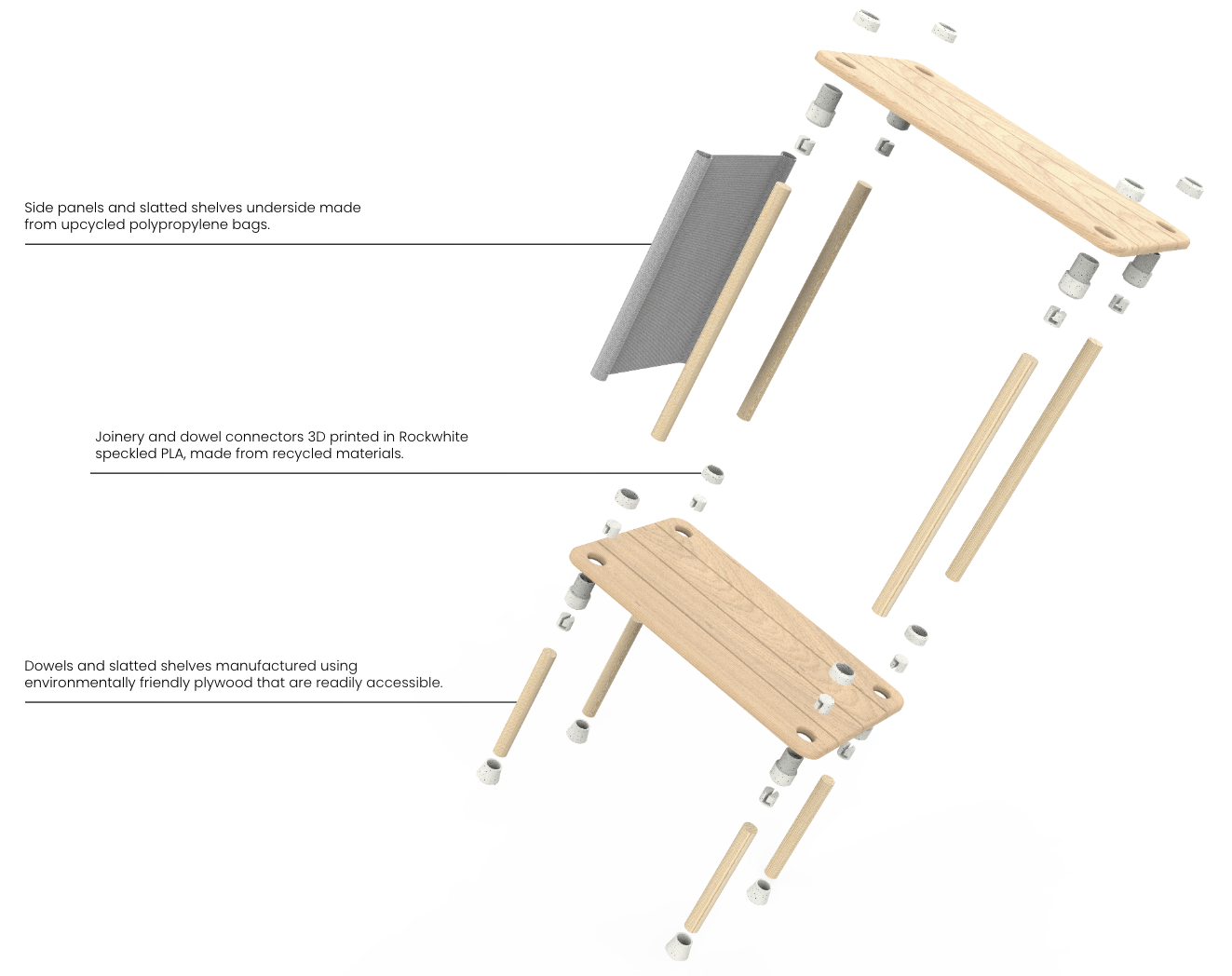

EXPLODED VIEW

FINAL MODEL

STARTER PRODUCT KIT

slat shelf x3

fabric panel x1

long dowel x4

short dowel x8

joinery x12

feet x6

bag x1

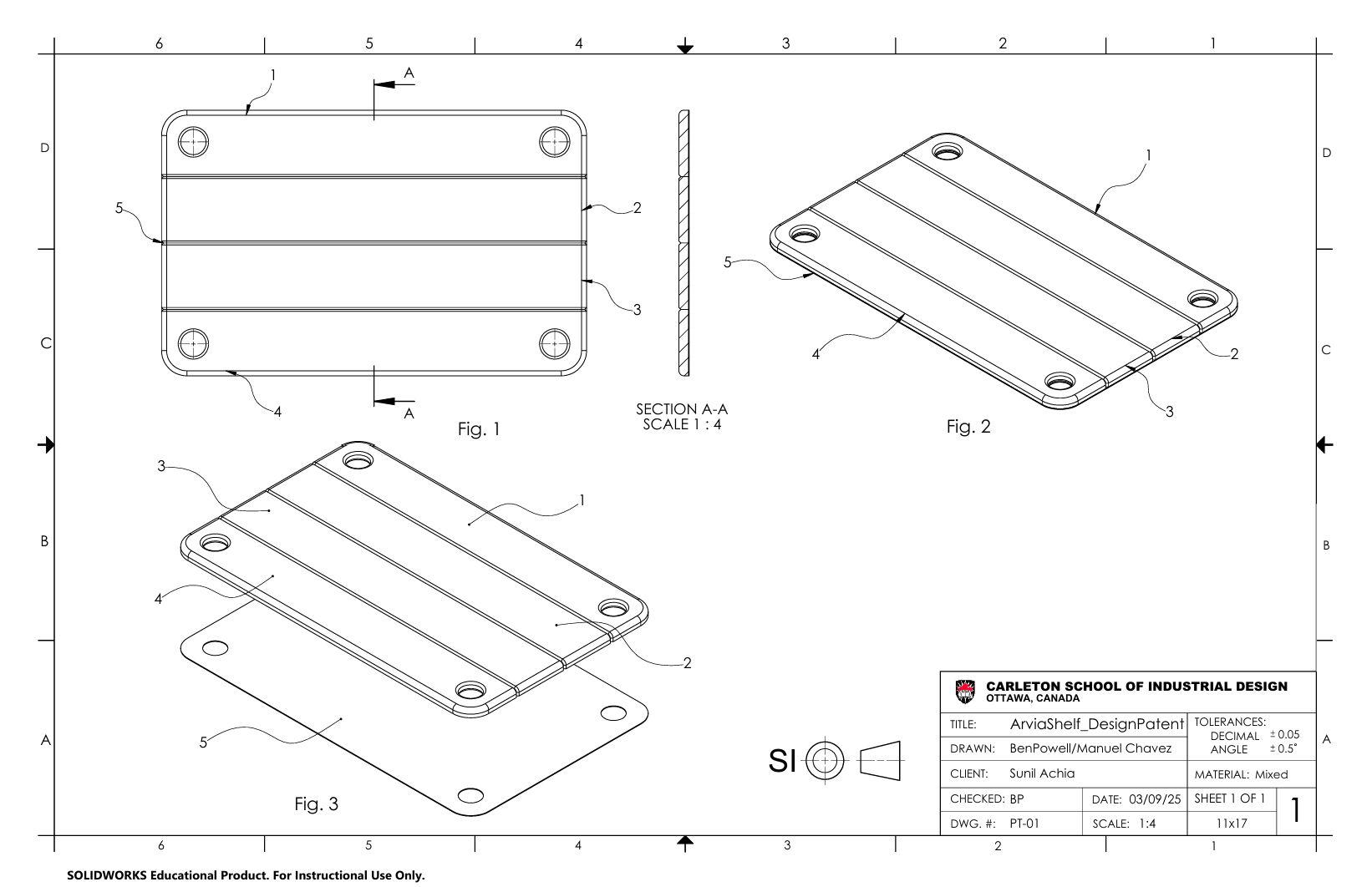

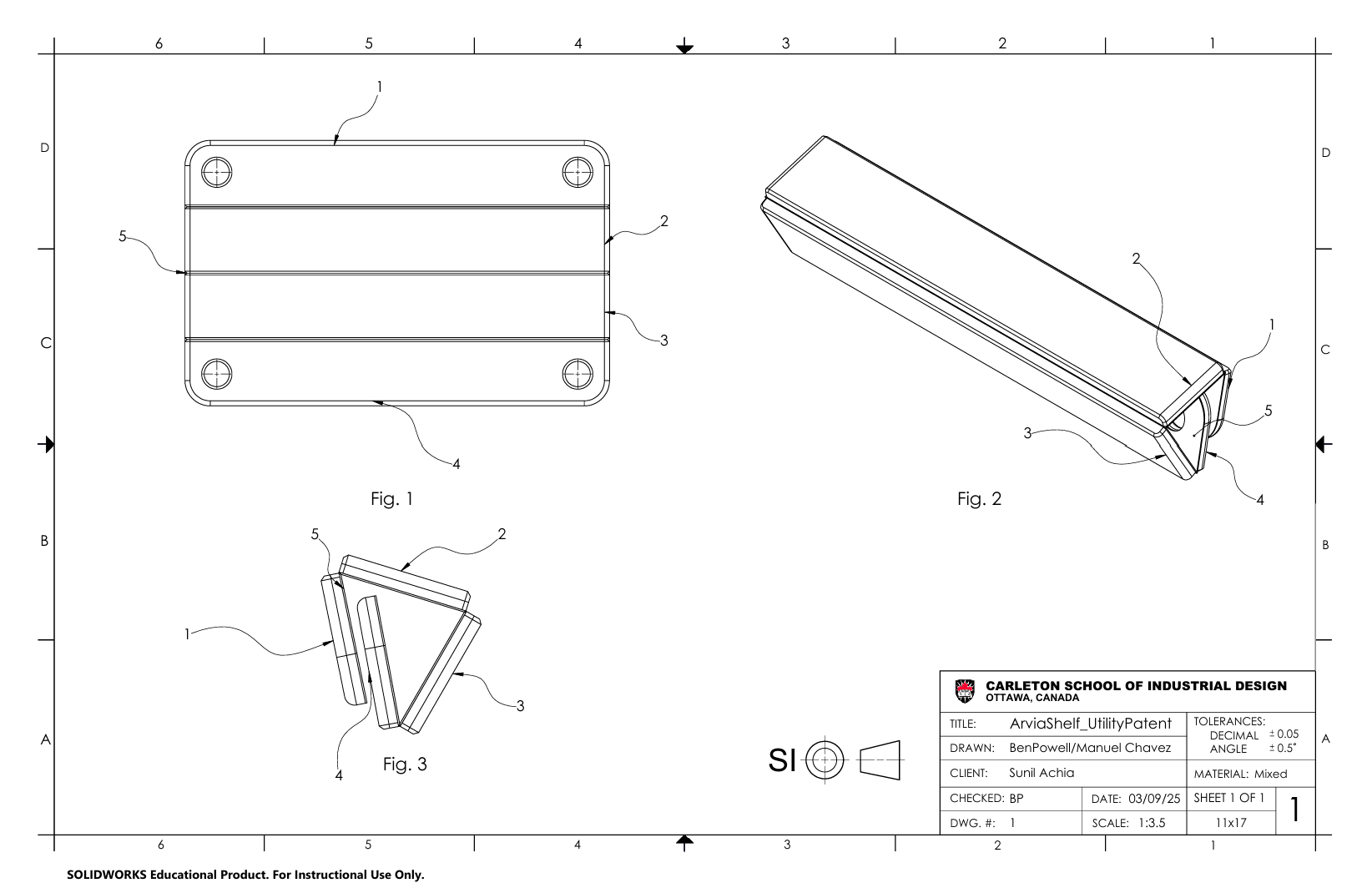

TECHNICAL PATENT DRAWINGS